Precast Box Culverts

INTRODUCING THE PRECAST BOX CULVERTS

LOOKS STRONG.

To build strong and sustainable precast bridges, we designed them to comply with Indian loading conditions for Highways and Railways. We made it with high-performance self-compacting concrete as per Japanese Industrial manufacturing standards.

HIGH-STRENGTH AND HIGH-PERFORMANCE PRECAST BOX CULVERT

LOADING CLASS 70 R, CLASS A, CLASS AA, INDIAN RAILWAY LOADING

TESTED FOR STRENGTH AND DURABILITY

ADVANCED JAPANESE MANUFACTURING AND WATER TIGHT TECHNOLOGY

APPROVED BY NUMEROUS GOVERNMENT AUTHORITIES

READY FOR

INSTALLATION

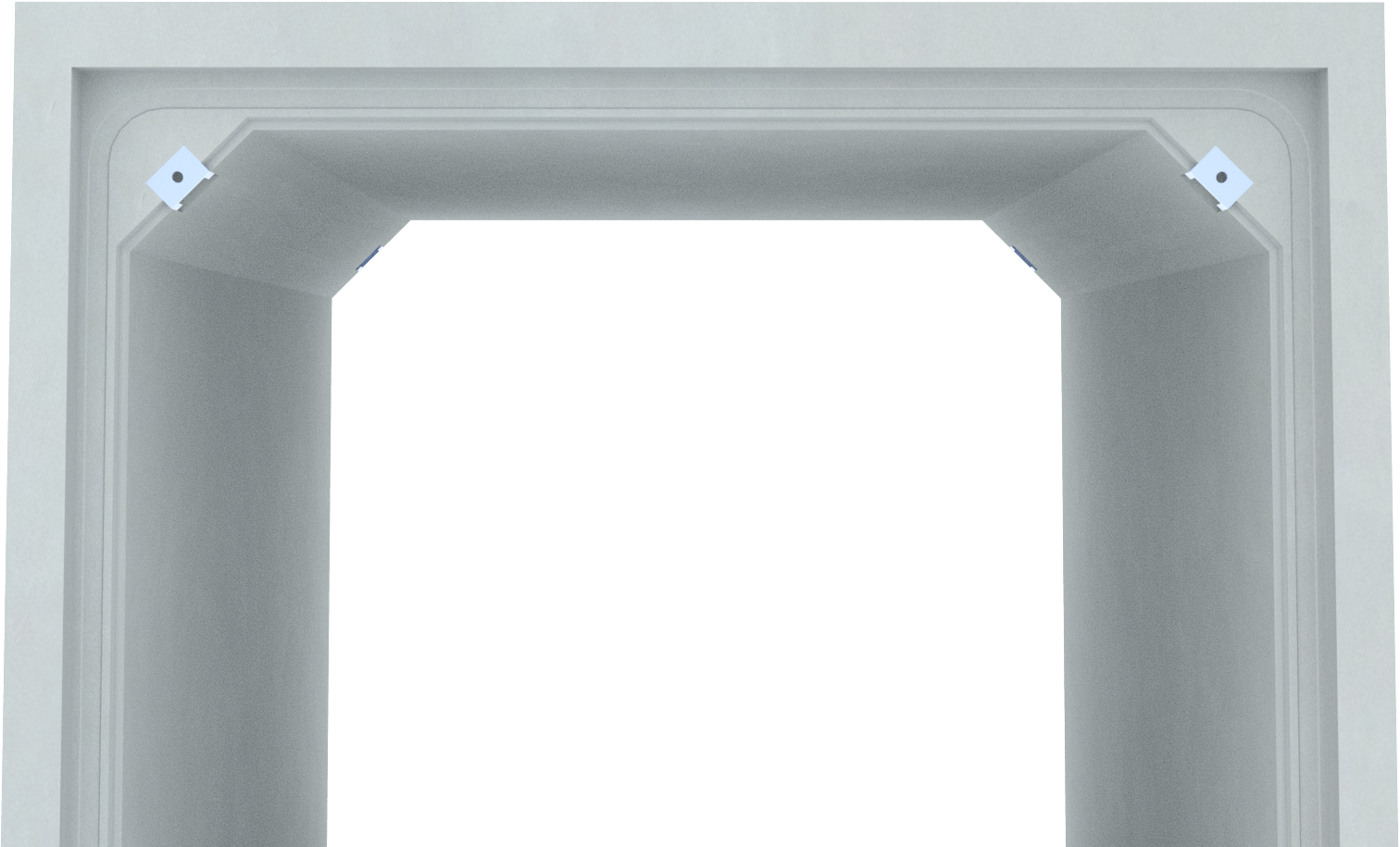

The Fuji precast box culvert gives you a quality and construction speed far superior to the cast-in situ alternative. It’s customisable for sizes and loads, just like the site requirement. This solution offers excellent versatility.

EVERYTHING

PERFECT AND PRECISE.

Unmatched dimensional accuracy and

tolerances unlike any other in civil infrastructure.

PRECISE

SEGMENT LENGTHS.

Close tolerances ± 5 mm. It enables the best predictions for the construction site, avoiding all the last-minute installation hassles.

STRAIGHT EDGES

Close tolerances ± 5 mm. It enables piece-by-piece fitting, just like Lego. It has no extraordinary gaps.

ACCURATE

THICKNESSES

Close tolerances ± 3 mm. Designed to perform and optimised to save.

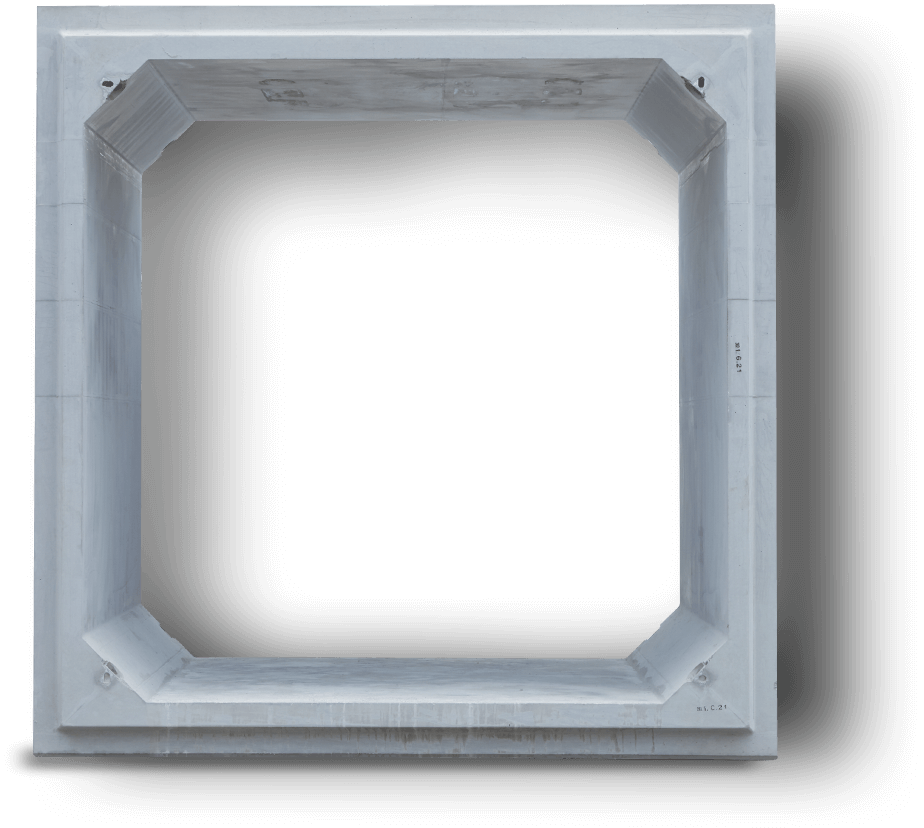

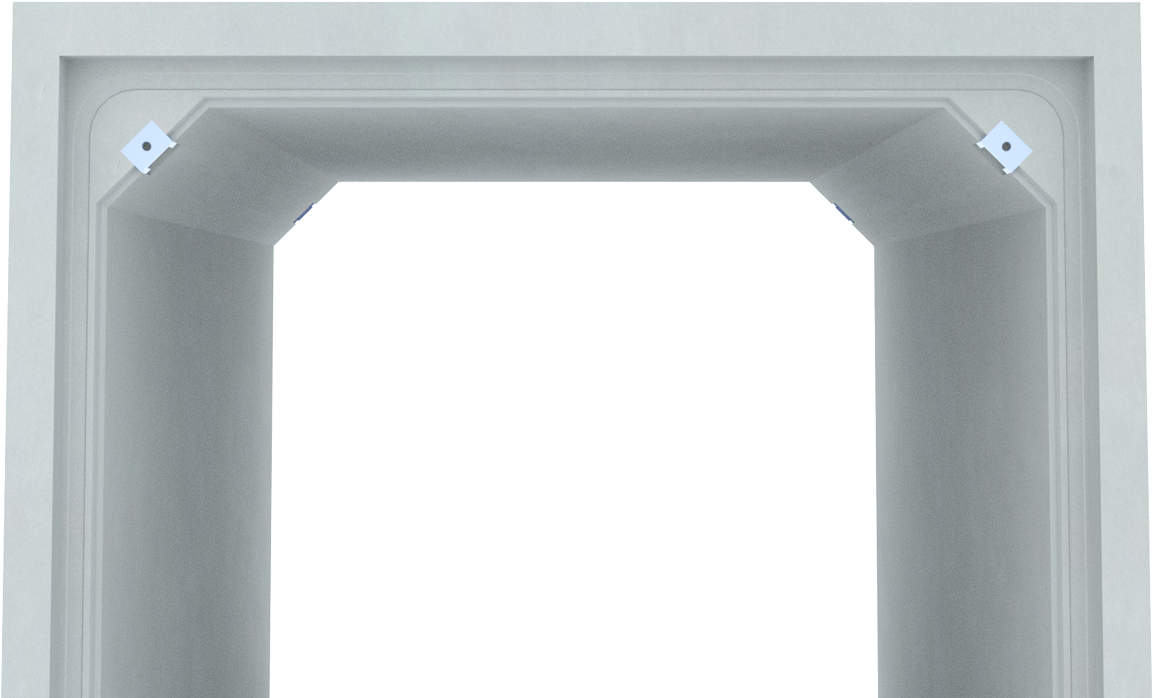

FEATURING FORM, FIT AND FUNCTION.

Uncompromised jointing arrangements in-built form as well as on-site connection to ensure fit and functionality after installation

MORTAR GROOVE

To fill in mortar for zero gaps leaving zero probability of leakage

RUBBER GASKET GROOVE

To fit in a rubber gasket that provides a water-proof character

FLANGE AND BOLT CONNECTION

To restrict construction movements at the site

SOCKET

To allow for a close and smooth transition of the plug side of the next segment

PLUG

To plug in for best fit in the socket side of the previous segment

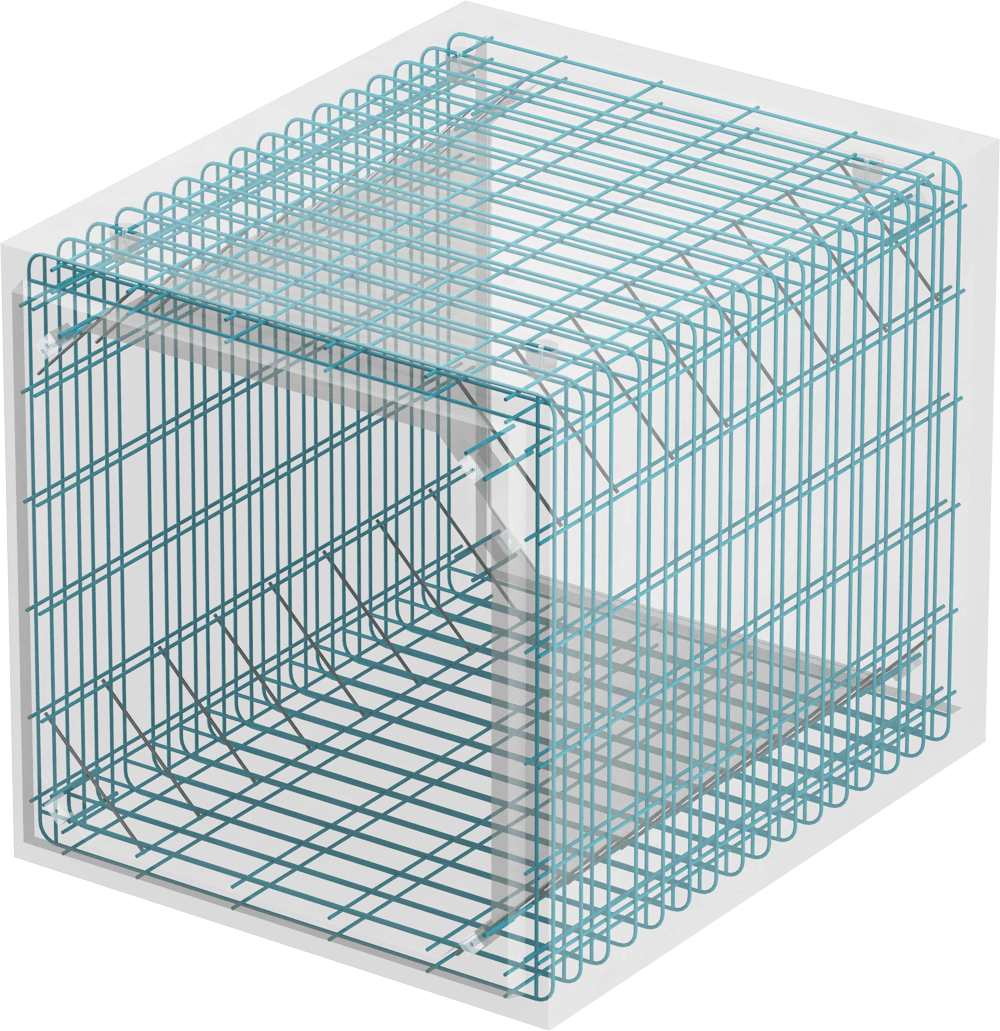

STRUCTURALLY

INTEGRATED

It is designed with high-performance concrete and high-strength steel to sustain project-specific loading for highway classes or railway categories.

- Reinforcement details

as per precast design - Type of steel and grade of concrete

(Fe500D/Fe550D) - Accurate in terms of cutting length,

curvature and spacing of rebars - Use of CPCC and CRS steel

for durability

LET’S REVOLUTIONISE THE PRECAST INDUSTRY

LET’S PRECAST THE FUTURE.

Roads & Bridges

Roads & Bridges