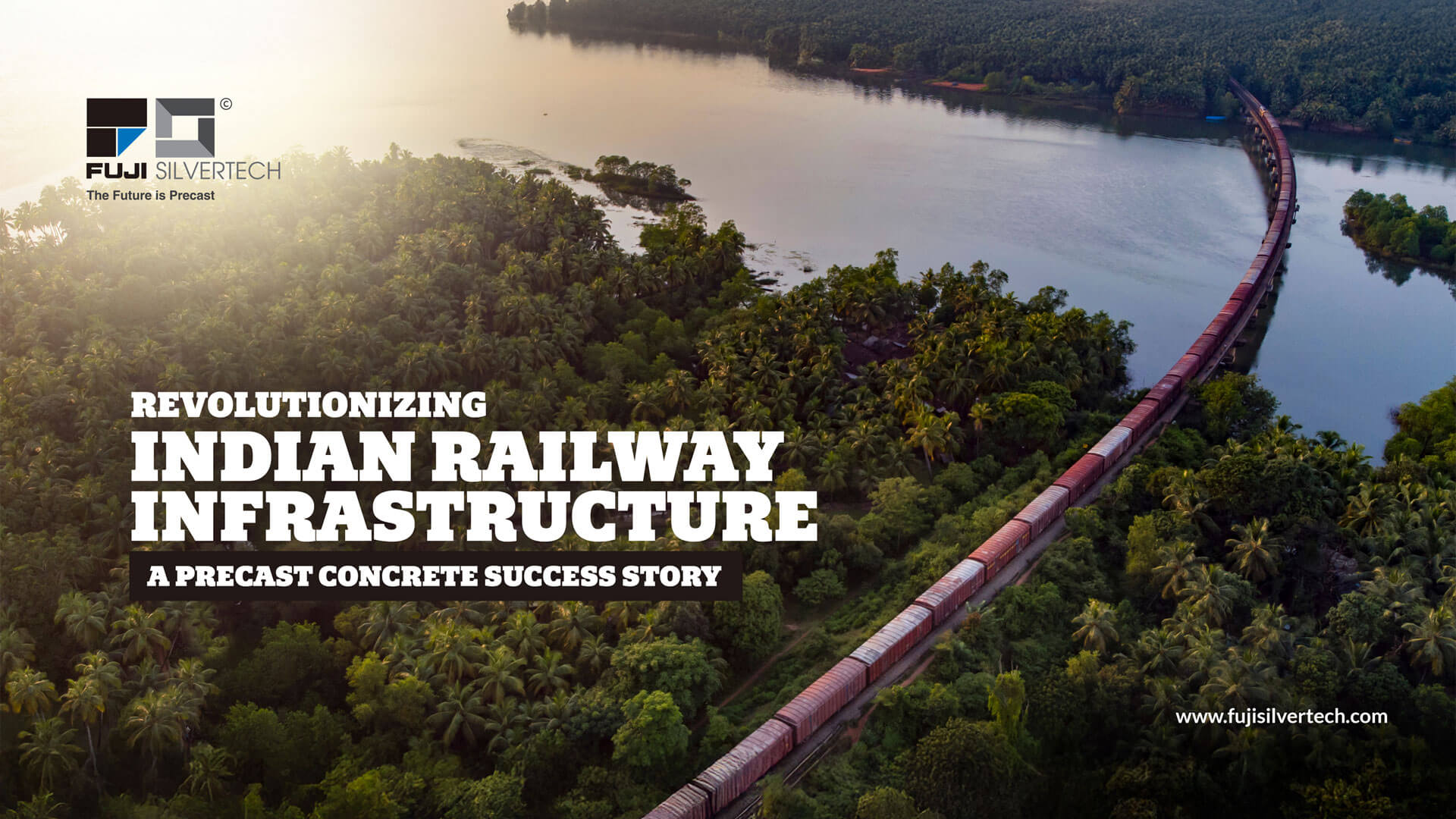

India’s railway network is the lifeline of the nation, and as our economy and trade expand, so does the demand for robust and efficient infrastructure. The Dedicated Freight Corridor (DFC) project, a monumental undertaking by the Ministry of Railways, aims to significantly upgrade our freight transportation capabilities. But building infrastructure of this scale, especially alongside active railway lines, comes with unique challenges. That’s where precast concrete technology, pioneered by Fuji Silvertech Concrete Pvt. Ltd., truly shines. Their innovative solutions for the DFC project offer a glimpse into the future of Indian Railway construction.

The Challenge

The DFC isn’t just about more tracks; it’s about stronger, higher-capacity infrastructure. Designed to carry freight at nearly twice the height and with significantly increased axle loads compared to standard Indian Railways, the DFC demands an unparalleled level of structural integrity. This means dealing with heavier loads and increased vibrational forces from trains moving at speeds exceeding 65 kmph.

A significant component of the DFC Infrastructure is its minor bridges and drainage and ducting infrastructure which runs along the tracks and is as long as them. Efficient storm water drainage and ducting parallel to these tracks is very crucial to avoid situations of waterlogging that compromise track stability and affect safety and longevity. Additionally, minor bridges and cross drainage structures along and across the DFC need to handle some of the highest transportation loading in the country.

Fuji Silvertech Advantage

Fuji Silvertech provided precast concrete solutions for track-side and cross drainage, minor bridges, and earth retention structures for the DFC. The core idea was to deliver solutions specifically tailored for the DFC, allowing for undisturbed railway operations and expedited project completion.

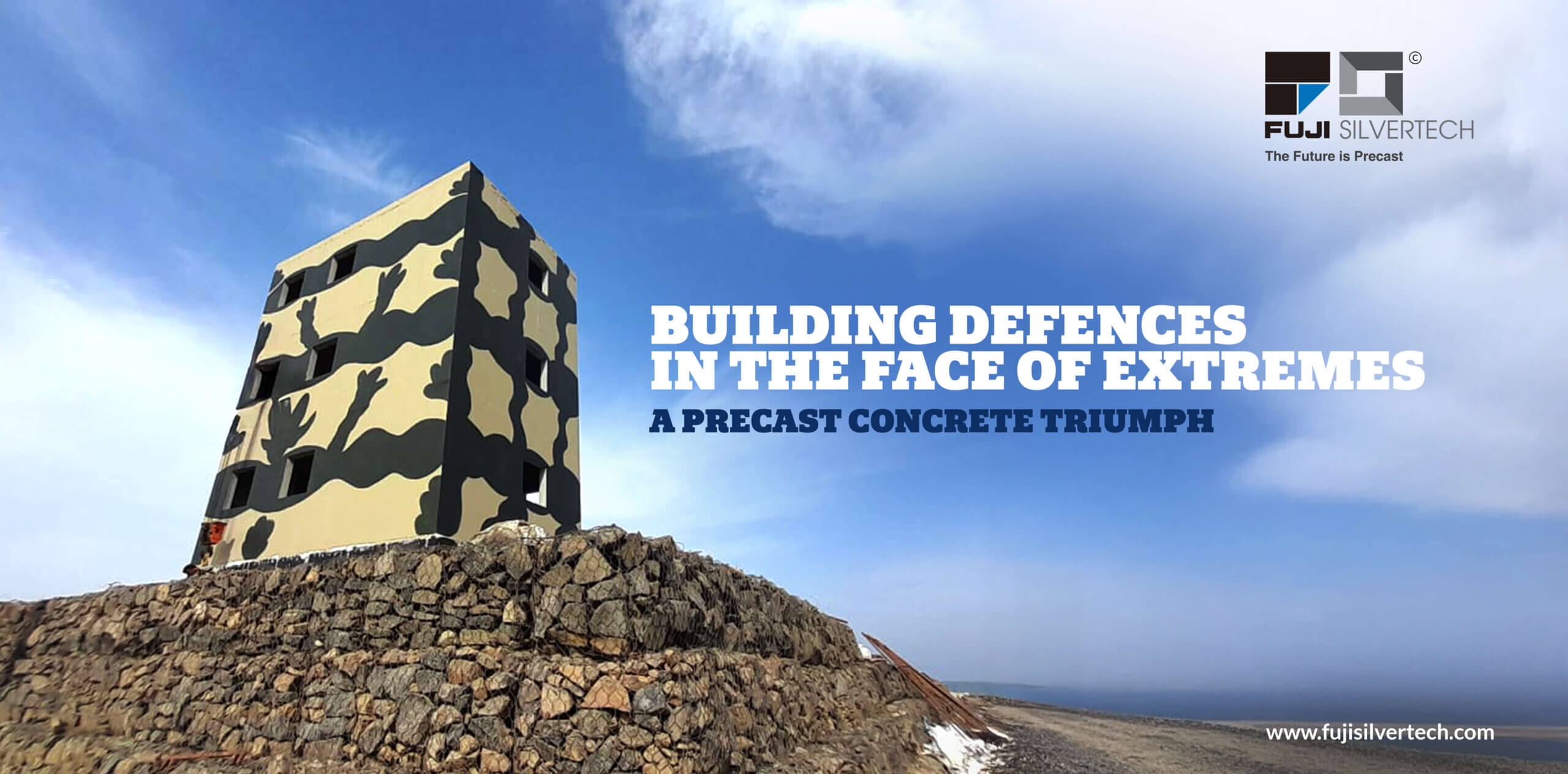

The unique aspect? These precast components were designed for easy, fast, and light site operations. Imagine the complexity of building 9.15-meter-tall retaining walls on-site next to an active railway line. Traditional cast-in-situ methods would involve massive construction activities. Fuji Silvertech’s T-shaped segmental precast retaining walls offered a game-changing alternative, designed to withstand both earth and rail vibrational loads. This innovation was so significant it was verified, validated and patented for safe earth retention and railway vibration effects.

Innovations Beyond Construction

The benefits of precast technology extend far beyond just speed and ease of installation. The precast technology offers vast potential in terms of customization, design, innovation and scalability.

In offering this simplicity and scalability of construction, there is a vast effort beyond the construction site – in the design, in the production and the dispatch. The solution was custom designed, a first-in-India attempt and further to the functional and structural requirements, a stringent design approval process by the regulatory and statutory authorities for IRS & DFCC ensures the technical compliance aspects of the product. The individual segments being huge, the challenges of mass concreting were obvious – and every threat of high hydration temperatures and cracking were carefully combated with different actions in production. The logistics and dispatch of these components had to be very dynamic because the dispatch locations moved with the tracks for the same project and the segments to be transported were larger than anything FUJI had done before. It was surely another first time for FUJI Silvertech and a huge challenge.

The challenge was true, but the goal was worthy, and it turned to a progressive realization with the hard work and determination of the FUJI team and the genuine support and right direction from all the authorities.

The modular nature of these precast components accelerated the construction fivefold compared to traditional methods. Imagine the time savings when scaled to projects involving 100+ km of drains and numerous minor bridges. Standardized and factory-made, these solutions are now ready for dispatch across the entire pan-India railway network.

Fuji Silvertech’s work on the DFC is a testament to the power of new-age precast concrete solutions. It showcases novel design for earth retention and cross-drainage, demonstrates high-quality and durable approaches for national infrastructure, and exemplifies a commitment to sustainable construction. This project isn’t just about today; it’s paving the way for a faster, more modern, integrated, and sustainable rail infrastructure for India’s future.

Roads & Bridges

Roads & Bridges